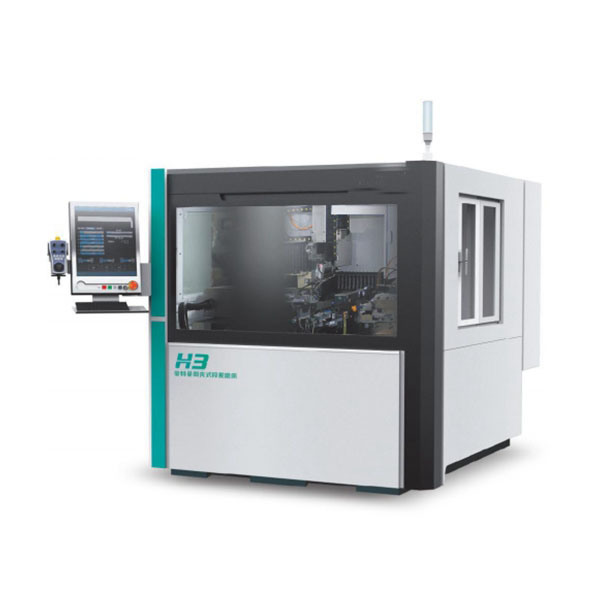

Product Introduction

Cheap manual flat grinding machines

|

The FM250 manual surface grinder uses P4 grade precision bearings for its spindle, which is highly reliable and easy to maintain.

• The machine tool uses double V plastic rails in the horizontal direction, one V and one flat in the vertical direction, and ball steel rails (integrally quenched), which have high stability and precision retention, and are easy and flexible to operate. Each moving part is centrally lubricated by hand-pulled oil pumps, and after being equipped with various special accessories, it can meet the grinding of arcs and other complex shapes. |

The FM250 manual surface grinder uses P4 grade precision bearings for its spindle, which is highly reliable and easy to maintain.

The machine tool uses double V plastic rails for the horizontal direction, one V and one flat rail for the vertical direction, and ball steel rails (with integral quenching), which have high stability and precision retention, and are easy and flexible to operate. Each moving part is centrally lubricated by hand-pulled oil pumps, and after being equipped with various special accessories, it can meet the grinding of arcs and other complex shapes. |

|

The FM250AH electric surface grinder is based on the FM250 surface grinder. The manual motion mechanism of the workbench and the carriage is changed to an automatic motion mechanism. The smooth movement of this mechanism can significantly improve the surface finish of parts, increase work efficiency, and reduce labor intensity. The automatic mode and manual mode can be flexibly switched. |

FM250YHAS hydraulic automatic digital display surface grinder converts the manual motion mechanism of the worktable in the X direction into a left and right hydraulic automatic system. The main mechanical valve of the system is a special valve for grinders, which is divided into two parts: mechanical reversing control and throttling speed control. The throttling speed control part also has a load unloading function, which can realize the start and stop of the worktable. This valve also has a buffer adjustment function. The Y axis is electric and manual and can be switched freely. The Z axis and Y axis are equipped with grating rulers. The machine tool has the characteristics of easy operation, flexible and reliable, no vibration, stable precision, good thermal stability, low noise, and easy maintenance.

|

|

•FM618 uses P4 grade precision bevel ball bearings, which are assembled in a temperature-controlled room after strict measurement and selection of pre-pressure to ensure the service life of the bearings and the surface roughness of the grinding.

●The front and rear slideways use a V-shaped and smooth path, and are precision scraped, which not only slides smoothly but also is wear-resistant, and is most suitable for forming grinding.

•The left and right ball tracks use high-precision steel balls. Wear-resistant, impact-resistant, easy to move: labor-saving, can greatly improve work efficiency. |

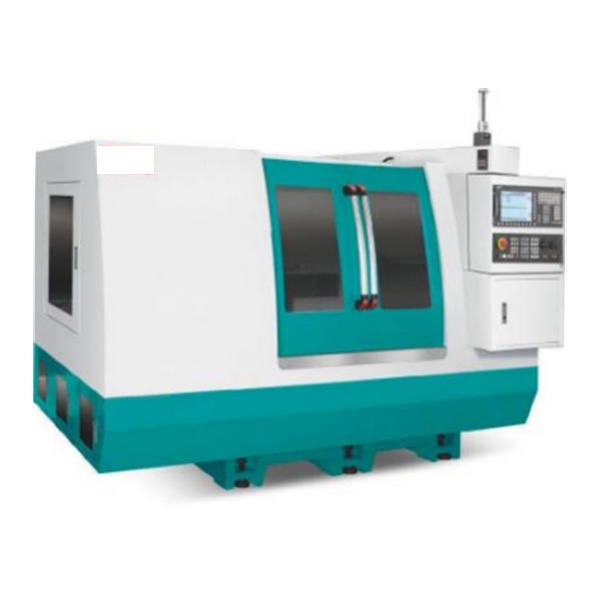

●FM820 manual surface grinder can grind various planes and complex shaped surfaces, and is suitable for grinding without motorized feed. The spindle adopts P4-level precision rolling bearings and labyrinth seals, which are waterproof and dustproof, and have smooth movement and high precision. The longitudinal direction adopts ball steel guide rails, which are easy and flexible to operate. The column adopts large-span guide rails, which have good rigidity and high stability. The whole machine adopts manual oil pump for centralized lubrication. |

|

• FM820AHS electric digital display surface grinder is based on M820 surface grinder. The manual motion mechanism of the worktable and the carriage is changed to an automatic motion mechanism. The smooth motion of this mechanism can significantly improve the surface finish of parts, increase work efficiency, and reduce labor intensity. The automatic mode and manual mode can be switched flexibly. |

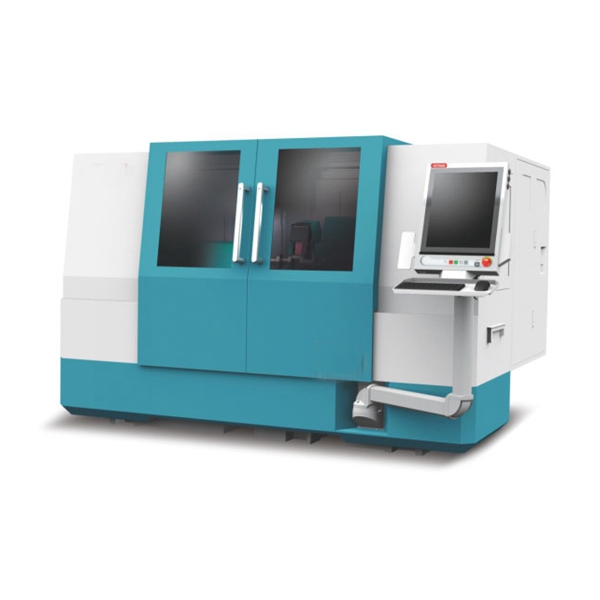

The hydraulic system of FMY3270 hydraulic surface grinder is composed of a set of motor-dosed pumps. The maximum flow of the pump is 18L/min, the motor power is 4KW, the working pressure of the pump can reach 3Mpa, and the system pressure is adjusted by the overflow valve. The main mechanical valve of the system is a special valve for grinders, which is divided into two parts: mechanical reversing control and throttling speed control. The throttling speed control part also has a load-unloading function, which can realize the start and stop of the workbench. This valve also has a buffer adjustment function. The machine tool has the characteristics of easy operation, flexibility and reliability, no vibration, stable precision, good thermal stability, low noise, and easy maintenance. |

|

|

|

|

NO |

Model |

FM250 |

FM250S |

FM250AH |

|

|

1 |

Worktable size |

500x250mm |

|||

|

2 |

Max move in left & right |

550mm |

|||

|

3 |

Max move in forward & backward |

280mm |

|||

|

4 |

Max distance between spindle center to worktable |

470mm |

|||

|

5 |

Max load on worktable |

100kgs |

|||

|

6 |

T slot worktable |

14x1mm |

|||

|

7 |

Worktable speed |

manual |

- |

0-25m/min |

|

|

8 |

Handwheel feed in forward & backward |

1 scale |

0.02mm |

||

|

9 |

1 circle |

2.5mm |

|||

|

10 |

Auto feed in forward & backward |

- |

- |

0.5-12mm |

|

|

11 |

Handwheel feed in forward & backward |

1 scale |

- |

0.02mm |

|

|

12 |

1 circle |

- |

2.5mm |

||

|

13 |

Grinding wheel size |

180x13x31.75/32mm |

200x17x31.75/32mm |

||

|

14 |

Spindle speed |

50HZ |

- |

2850rpm |

|

|

15 |

60HZ |

- |

3420rpm |

||

|

16 |

Handwheel feed in up & down |

1scale |

- |

0.01mm |

|

|

17 |

1circle |

- |

1.25mm |

||

|

18 |

Spindle motor |

1.5kw |

|||

|

19 |

Hydraulic motor |

- |

|

- |

|

|

20 |

Vacuum cleaner motor |

- |

|

-- |

|

|

21 |

Coolant motor |

40w |

|||

|

22 |

Drive motor in forward & backward |

|

|

60w |

|

|

23 |

Layout size |

2500x1500x1800mm |

|||

|

24 |

Net weight |

1000kgs |

|||

|

25 |

Gross weight |

1100kgs |

|||

English

English Español

Español Pусский

Pусский

Lily

Lily