Product Introduction

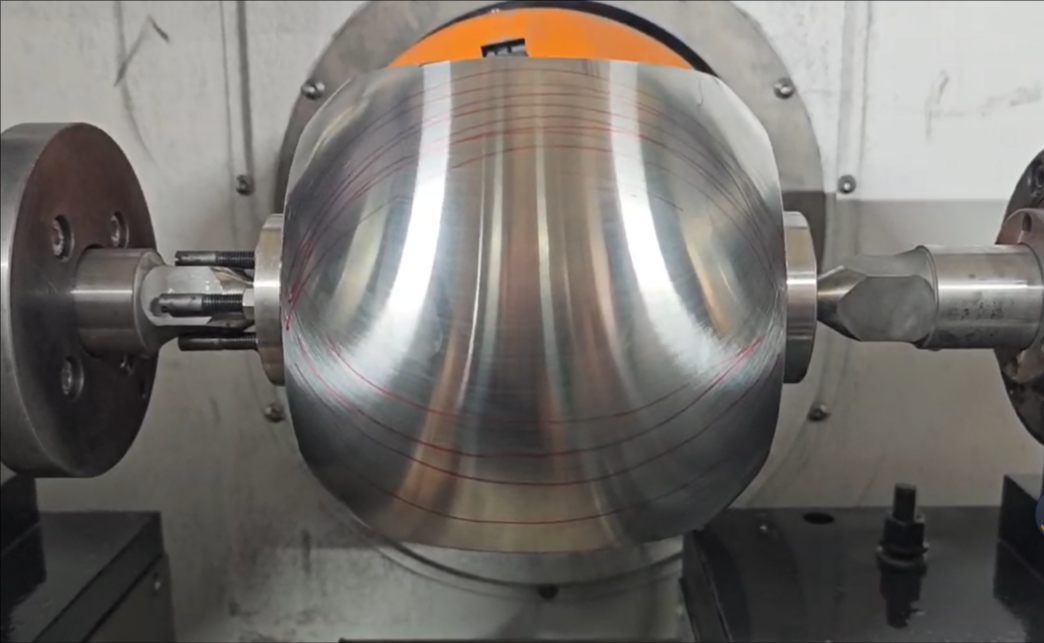

Ball grinding machines for ball workpieces

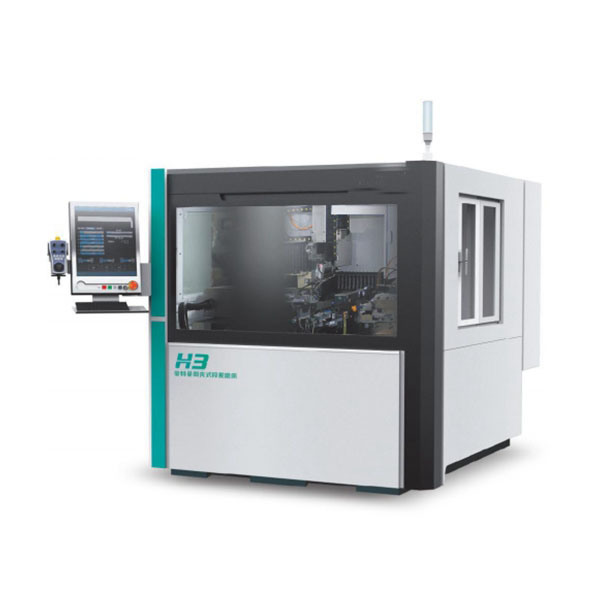

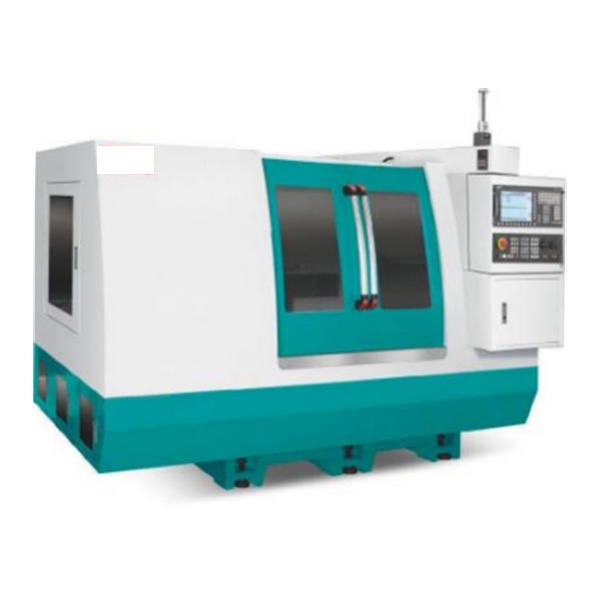

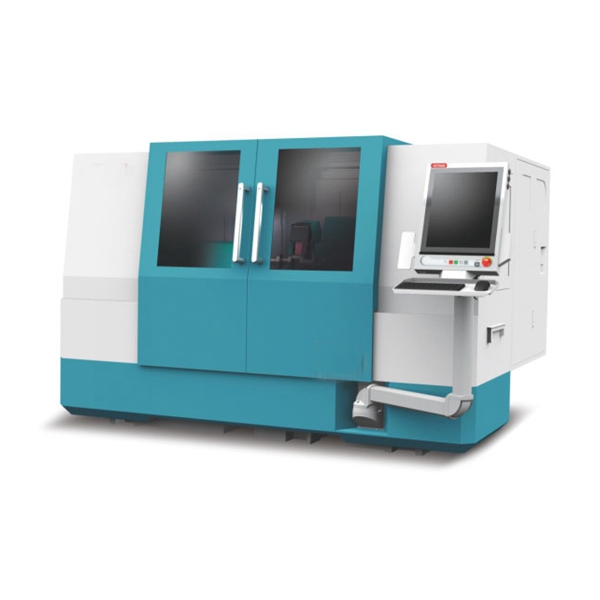

Specialized in the production, sales and technical services of CNC spherical grinders, spherical lathes and other products. The spherical grinder is widely used in ball valve processing and manufacturing, valve ball manufacturers, petrochemicals, valve repair centers and other mechanical processing industries with its high rigidity, high stability, high precision and price advantages.

The spherical grinder can process valve balls of various materials from DN15 to DN1600. From design and development to production, manufacturing, assembly to quality control inspection, each stage is strictly monitored to ensure quality and stability. The company has various advanced scientific research and testing equipment, and its manufacturing and processing capabilities are at the advanced level in the industry. The characteristics and performance of each equipment can be customized according to user needs to provide customers with better processing effects and increase higher production capacity. The company has passed the EU CE certification. After years of unremitting efforts, Kemi's spherical grinders have been exported to more than a dozen countries including Russia, Italy, Indonesia, India, the United States, Argentina, Mexico, and the United Kingdom. "Quality first, customer first" is the basic concept of Kemi's CNC machine tool development. Kemi has a professional technical R&D team and a complete production, marketing, and after-sales system, which can provide users with a one-stop complete solution in the CNC field.

|

Item |

Unit |

Main Technical Parameters |

||||||||||||

|

QM100 |

QM150 |

QM300 |

QM500 |

QM600 |

QM800 |

QM105Q |

M12000 |

QM1600 |

QM380 |

QM580 |

QM880 |

|||

|

Maximum Sphere OutsideDiameter |

mm |

φ30-φ160 |

φ37-φ240 |

φ120-φ400 |

φ400-φ740 |

φ450-φ900 |

φ580-φ1200 |

φ900-φ1535 |

Φ1100-φ1800 |

φ1500-φ2400 |

φ88-Φ320 |

φ240-φ560 |

φ580-φ1100 |

|

|

Maximum Sphere Inner Diameter |

Inch |

1/2“-4” |

1”-6” |

3“-10” |

10”-20” |

12”-24” |

16“-32” |

24”-42” |

30”-48” |

40” 64 |

2“-8” |

6”-16” |

16“-30” |

|

|

Distance between center to worktable |

mm |

120 |

140 |

220 |

400 |

500 |

650 |

850 |

920 |

1250 |

250 |

315 |

630 |

|

|

Max Sphere Weight |

Kg |

50 |

100 |

200 |

1000 |

1200 |

4000 |

10000 |

15000 |

20000 |

200 |

1000 |

2000 |

|

|

Grinding Wheel Spindle Motor Power |

KW |

4.0 |

5.5 |

15 |

37 |

37 |

45 |

55 |

55 |

75 |

15 |

37 |

45 |

|

|

Spindle Speed |

Rpm |

100~3000 |

100~2800 |

100-1800 |

100-1200 |

100~900 |

100~900 |

100~800 |

100~600 |

100~500 |

100~1800 |

100~1200 |

100~800 |

|

|

Headstock Rotating Torque |

NM |

>40 |

40 |

>50 |

>120 |

>150 |

>180 |

2KW |

3KW |

4KW |

>50 |

>120 |

>180 |

|

|

Headstock Speed |

Rpm |

3-50 |

3-40 |

3-35 |

3-30 |

3-25 |

3-20 |

3-20 |

3-15 |

3-10 |

6-125 |

6-125 |

6-125 |

|

|

X/Z travel

|

mm |

150/120 |

150/150 |

250/220 |

400/350 |

500/400 |

600/500 |

700/600 |

800/600 |

800/600 |

600/400 |

800/500

|

1000/800 |

|

|

Adjustment of tailstock |

mm |

200 |

250 |

350 |

450 |

450 |

|

|

|

|

|

|

|

|

English

English Español

Español Pусский

Pусский

Lily

Lily