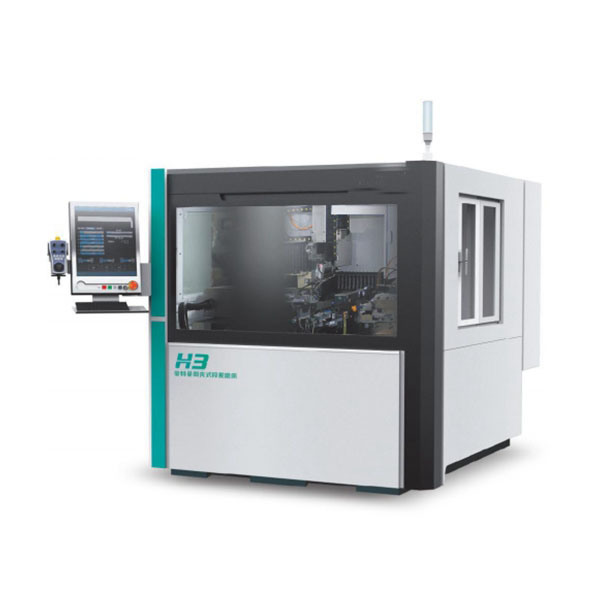

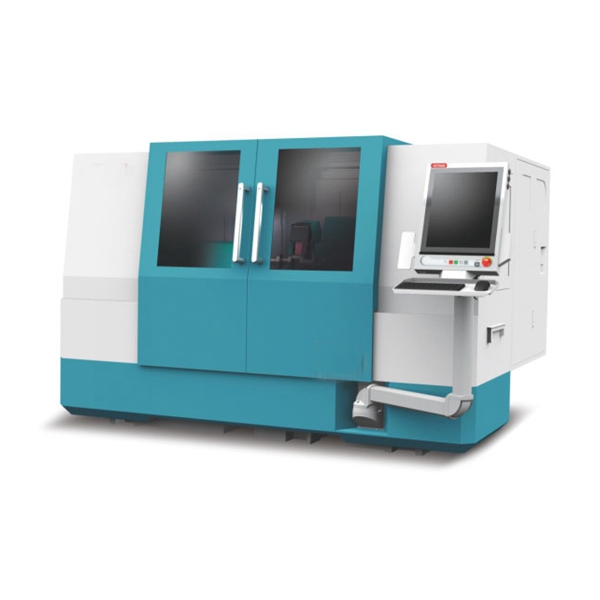

Product Introduction

CNC high precision Optical curve grinders

1.2, Machine functions overview

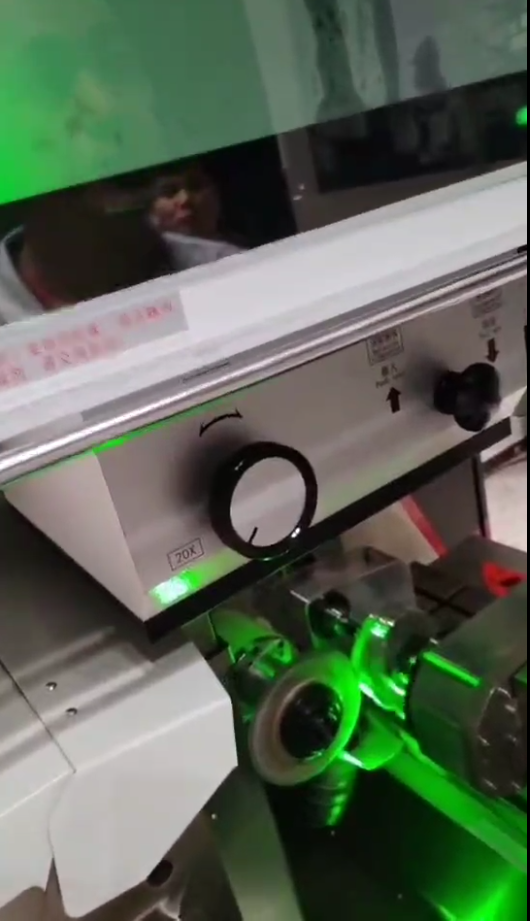

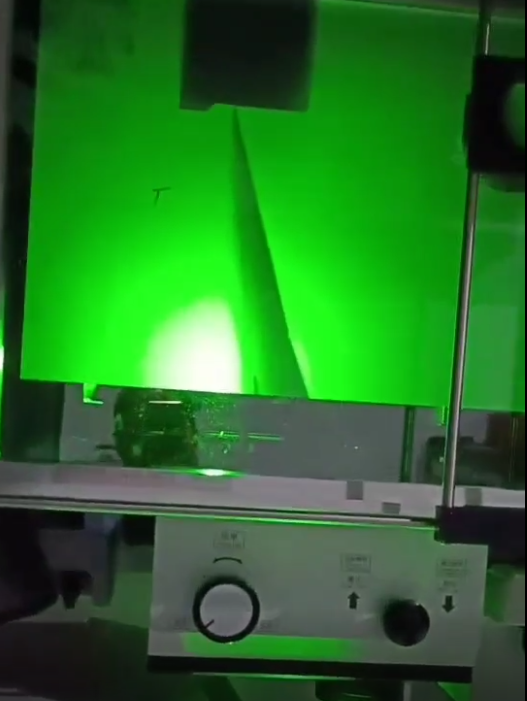

Optical curve grinders are used to grind precise and complex surfaces, including straight lines, arcs, and curves. The shape of the processed curve is reflected by the refraction of light. It can process grooves, inner and outer radius, and tools with complex shapes and high dimensional requirements for high-precision parts. During the grinding process, the workpiece and grinding wheel can be magnified 20 times or 50 times by the optical system and projected on the screen. When working, the grinding wheel can be observed on the screen at any time along the workpiece surface, and compared with the film magnification image of the workpiece image magnified 20 times or 50 times. The projected magnified image can be magnified again with a visual amplifier, and its processing status can be observed online. The processing program can be manually interrupted or compensated (if there are factors such as grinding wheel wear, materials, feed rate, etc., they can be compensated and changed in time) to achieve the consistency between the sample processing surface and the film magnification image. After processing, the workpiece can also be checked by projection, which is intuitive and clear. Whether during or after processing, deviations can be observed and corrected in time, and the quality of the processed sample can be known without additional inspection.

1.2.1 Equipment bed, connectors, lifting platform and other parts should all be made of high-quality castings, which should be annealed and treated to eliminate stress. Castings should be reasonably calculated, optimized, and have reasonable structural strength and reinforcement ribs to provide high-rigidity mechanical support.

1.2.2 Use well-known brand ball screws and guide rails, and use a fully closed-loop 0.0001mm grating ruler for measurement to ensure axial running accuracy and ensure processing accuracy ≤±0.002mm.

1.2.3 Use a high-speed, high-precision spindle 24000min-1.

1.2.4 Use a precision-grade high-precision projection system with 20x and 50x magnifications that can be switched; transmitted light and incident light use energy-saving well-known brand LED light sources to ensure ultra-long service life.

1.2.5 Configure a visual magnifier to further enlarge the image for easy observation.

1.2.6 Configure a CNC machining system, which can be automatically processed according to the program or manually operated.

1.2.7 Interrupt the program at any time during the machining process and correct the machining error at any time.

1.2.8 The control system should be able to realize 4-axis linkage (2-axis interpolation) automatic processing to improve its processing efficiency.

1.2.9 Equipped with a precision digital display lifting workbench to achieve fine-tuning of lifting and lowering, and the display screen displays the lifting displacement.

1.2.10 Equipped with a 0-150mm high-speed reciprocating grinding wheel lifting table with three-degree-of-freedom adjustment.

1.2.11 Safety protection

Equipped with reliable and effective safety protection devices to protect the personal safety of operators; the safety protection devices are simple and practical, easy to operate, and do not excessively increase the size of the machine tool body.

It has a system safety integration function to ensure the safety of personnel and equipment during operation, accidental power failure, etc.

1.2.12 The selection of various types of sample preparation tools must have high processing quality, good processing stability, and high processing efficiency.

2、Equipment technical data.

2.1 Equipment Parameters

|

Model |

FP-1X |

|

Max Grinding length (steps grinding) 最大磨削长度(分段磨削) |

200 mm |

|

Max grinding thickness 最大磨削厚度(Max) |

100 mm |

|

Max grinding depth 最大磨削深度(Max) |

17 mm |

|

Max grinding diameter of bars 最大磨圆直径(Max) |

200 mm |

|

Max grinding length of bars 最大磨圆长度(Max) |

180 mm |

|

Max projection area 一次投影的最大区域(Max) |

21×27.5mm 8.4×10.8 mm |

|

Mini moving scale of worktable 工作台最小移动刻度 |

0.0001mm |

|

Longitudinal travel of worktable (Y) 工作台纵向行程(Y) |

230mm |

|

Horizontal travel of worktable (X) 工作台横向行程(X) |

140 mm |

|

Vertical travel of worktable (Z) 工作台垂直行程(Z) |

110 mm |

|

Size of worktable 工作台台面面积 |

400×250 mm |

|

Grind wheel diameter砂轮直径 |

75 mm |

|

Grind wheel speed砂轮转速 |

1000~24000 rpm |

|

Grind wheel lifting speed砂轮升降速度范围 |

10~10000 mm/min |

|

Mini grind wheel feeding move scale 砂轮进给移动最小单位 |

0.0001mm |

|

Slide reciprocating travel滑板往复行程 |

0~150 mm |

|

Slide reciprocating speed滑板往复速度 |

0~400 strokes/min |

|

Grind wheel frame rotation around longitudinal horizontal axis (X) 砂轮架绕纵向水平轴转动量(X) |

-2°~+5° |

|

Grind wheel frame rotation around horizontal axis (Y) 砂轮架绕横向水平轴转动量(Y) |

±10° |

|

Grind wheel frame rotation around vertical axis (Z) 砂轮架绕垂直轴转动量(Z) |

±15° |

|

Slide seat longitudinal travel(X) 滑座纵向行程(X) |

190 mm |

|

Slide seat horizontal travel(Y)滑座横向行程(Y) |

140 mm |

|

Projection magnification 物镜放大倍数 |

20& 50 |

|

Screen size 投影屏幕尺寸 |

540×420 mm |

|

Software screen size数控显示器尺寸 |

10.4inch |

|

Control axes number控制轴数 |

4 axis (simultaneous 2 axis) 4-4轴联动(2轴插补) |

|

Control handwheel number 控制手轮数 |

2(X/Y、Z/V) |

|

Led type 照明形式 |

Refraction, reflection 透射、反射 |

|

Grindwheel spindle motor砂轮主轴电机 |

2.2 kw |

|

Grindwheel slide reciprocating motor 砂轮滑板往复电机 |

1.85 kw |

|

Machine total power机床总功率 |

8.5 kw |

|

Vacuum cleaner motor 吸尘器电机 |

1.5 kw |

|

Power supply |

380V, 50HZ, 3P |

|

Machine dimension (L*W* H) 机床外形尺寸(长X宽X高) |

1800×2300×2100 mm |

|

Machine weight 机床重量 |

4500 kg |

English

English Español

Español Pусский

Pусский

Lily

Lily