Honing is a high-precision and high-efficiency hole machining process. Honing machines are specialized machine tools used to perform this high-precision hole machining process. There are horizontal honing machines, vertical honing machines, deep hole honing machines, and other series. Honing tools are special tools used on honing equipment. They come in a variety of sizes and types, but tools within a certain specification range can be used on the same honing machine to achieve the purpose of processing different products.

With the development of technology, various industries have very high requirements for products and parts, resulting in an increasingly wide range of honing applications. Currently, the main industries include aerospace, automotive parts, engines, motors, oil pumps and nozzles, hydraulic cylinders, and sewing machines. In short, honing can achieve the required precision for any commonly used product's holes.

honing tools is optimized using a siding system to handle a wide variety of honing machine materials, such as NaKaSil, hard chrome, aluminum, various oxide layers, free-cutting steel, tool steel, quenched and tempered steel, and gray cast iron.

Product Advantages

(1) It is simple to operate, quick and easy to carry out, and suitable for honing tools to grind holes in various materials;

(2) Ensure high precision in the geometric dimensions of the hole (less than 0.05 / m Ra);

(3) After honing, the surface roughness of the brushed surface can be less than 0.02 / m Ra;

(4) It is a cost-effective tool for grinding pipe holes;

(5) Grinding materials with a gear measuring instrument with low tool cost, resulting in high economic efficiency.

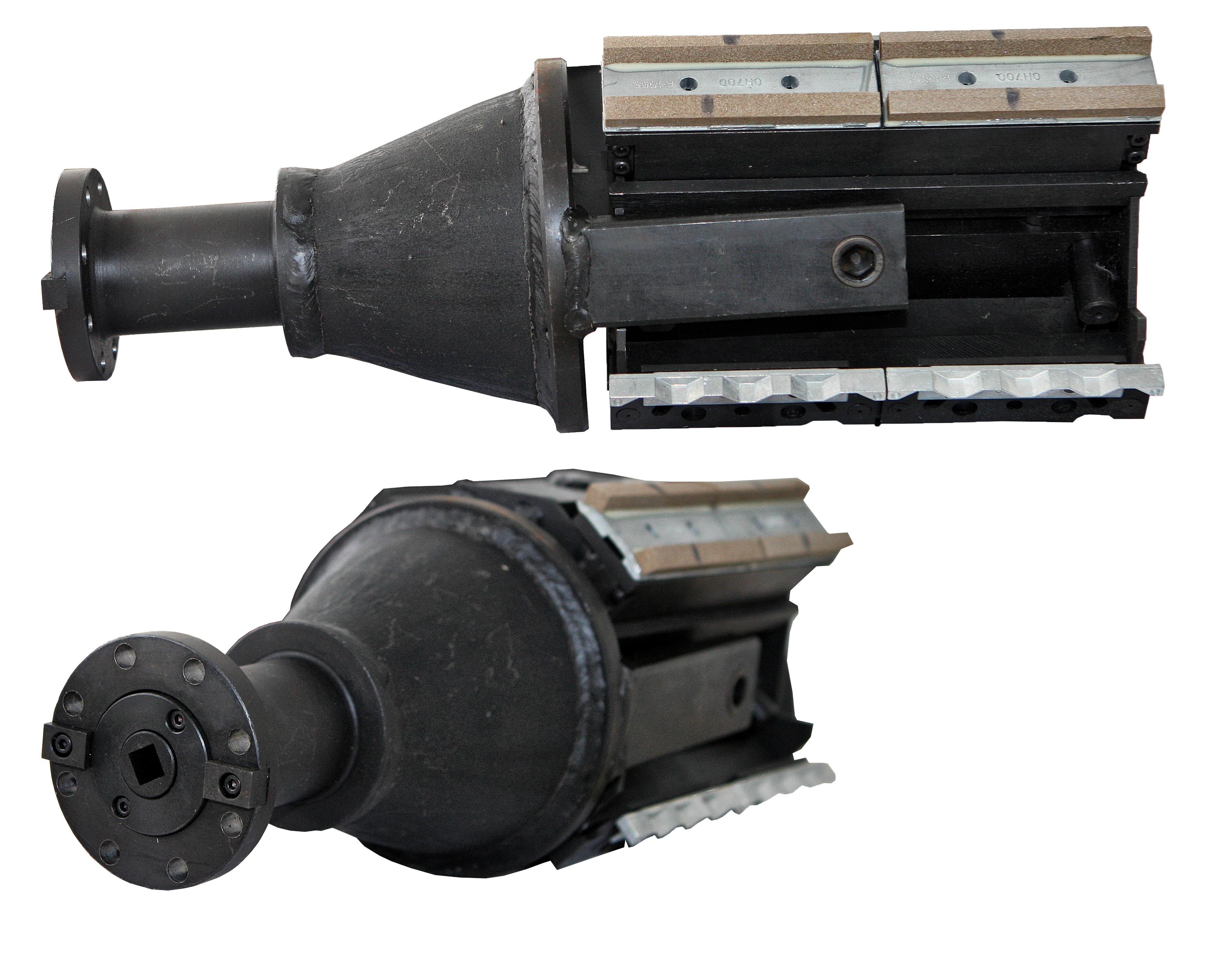

Showcase of some of our honing tools

English

English Español

Español Pусский

Pусский

Lily

Lily