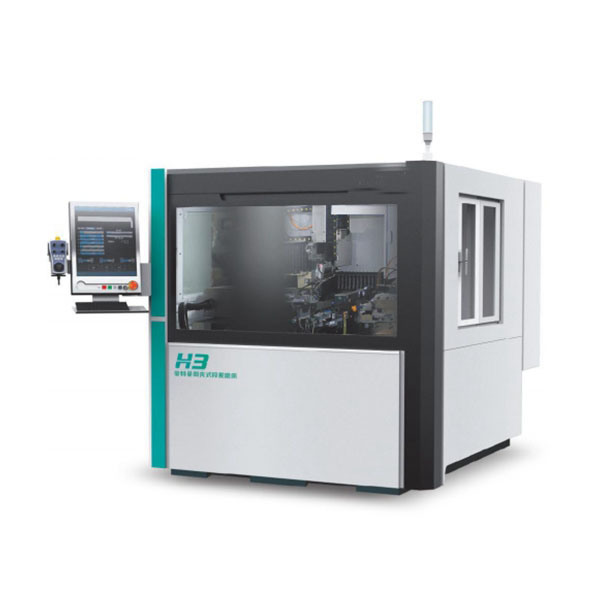

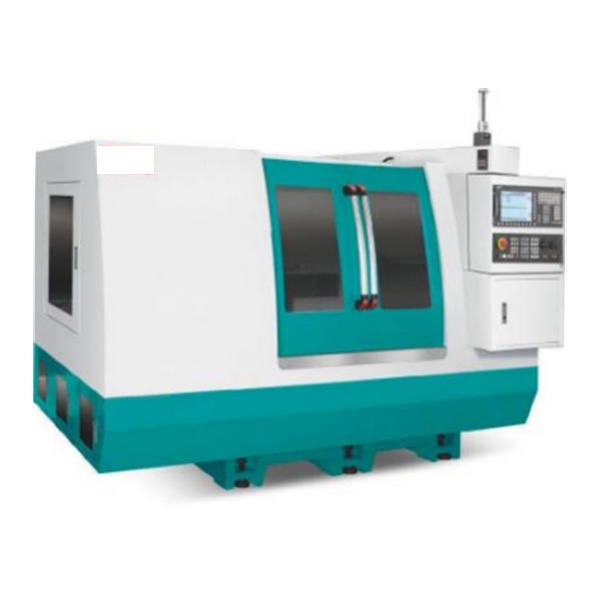

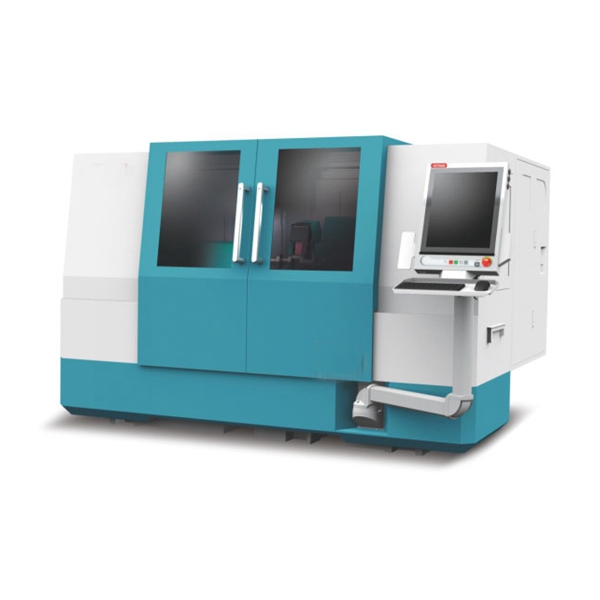

Product Introduction

1、 Machining Accuracy:

After grinding with a centerless grinder, the following standard accuracy requirements must be met: (different grinding wheels are used for workpieces made of different materials)

Note: In general, the grinding amount is coarse grinding (0.03~0.06mm); fine grinding (0.005~0.02mm)

|

No. |

Grinding |

Workpiece |

Real roundness

|

Ra |

Remarks |

|

1 |

Through grinding |

Standard sample |

≤0.001mm |

≤Ra0.3 |

Sample shorter than 100mm with right wheel |

|

2 |

Plunge grinding (pressure grinding) |

Standard sample |

≤0.001mm |

≤Ra0.3 |

Sample shorter than 100mm with right wheel |

|

NO |

Items |

Unit |

Model :FX-12S |

Model :FX- 18S/( Advanced AS/BS ) |

|

1 |

Processing diameter range |

mm |

Φ0.5-40 |

Φ1-60( customzied to 100) |

|

2 |

Grinding wheel size ( OD*W* ID) |

mm |

Φ305*150*Φ120 |

Φ455*205*228.6 |

|

3 |

Adjust wheel sie ( OD*W* ID) |

mm |

Φ205*150*Φ90 |

Φ255*205*111.2 |

|

4 |

Grinding wheel rotation |

RPM |

1950 |

1500 |

|

5 |

Adjust wheel rotation |

RPM |

0-320 |

0-250 |

|

6 |

Grinding wheel drive mtotor |

KW |

5.5 |

11.5 |

|

7 |

Adjust wheel motor (servoi motor) |

KW |

2.0 |

3.0 |

|

8 |

Oil pressure pump drive motor |

KW |

0.75 |

0.75 |

|

9 |

Cooling pump drive motor |

KW |

0.125 |

0.25 |

|

10 |

Adjust wheel feeding handwheel |

mm |

3.5/R 0.02/scale |

3.5/R, 0.05/scale |

|

11 |

Adjust wheel fine adjustment hand wheel |

mm |

0.1/R 0.001/scale |

0.1/R 0.001/scale |

|

12 |

Worktable feeding handwheel |

mm |

7/R 0.05/scale |

9.0/R 0.10/scale |

|

13 |

fine adjustment handwheel |

mm |

0.2/R 0.001/scale |

0.2/R 0.001/scale |

|

14 |

Dressing feeding handwheel |

mm |

1.5/R 0.01/scale |

2.0/R 0.01/scale |

|

15 |

Adjust wheel tilt angle |

Deg |

+5°~-3° |

+6°~-3° |

|

16 |

Adjust wheel rotation angle |

Deg |

±6° |

±6° |

|

17 |

Machine dimension |

mm |

1800×1400×1450 |

2350×1960×1550 |

|

18 |

Package size |

mm |

2350×1650×1770 |

2900×2400×1850 |

|

19 |

Machine weight |

Kg |

1800 |

2850 |

|

20 |

Package weight |

Kg |

2000 |

3000 |

English

English Español

Español Pусский

Pусский

Lily

Lily